Multijet Fusion

- Home

- Competences

- Additive Manufacturing

- Multijet Fusion

For particularly delicate contours

With the multi-jet fusion process (MJF) we offer potential for higher speeds and greater flexibility.

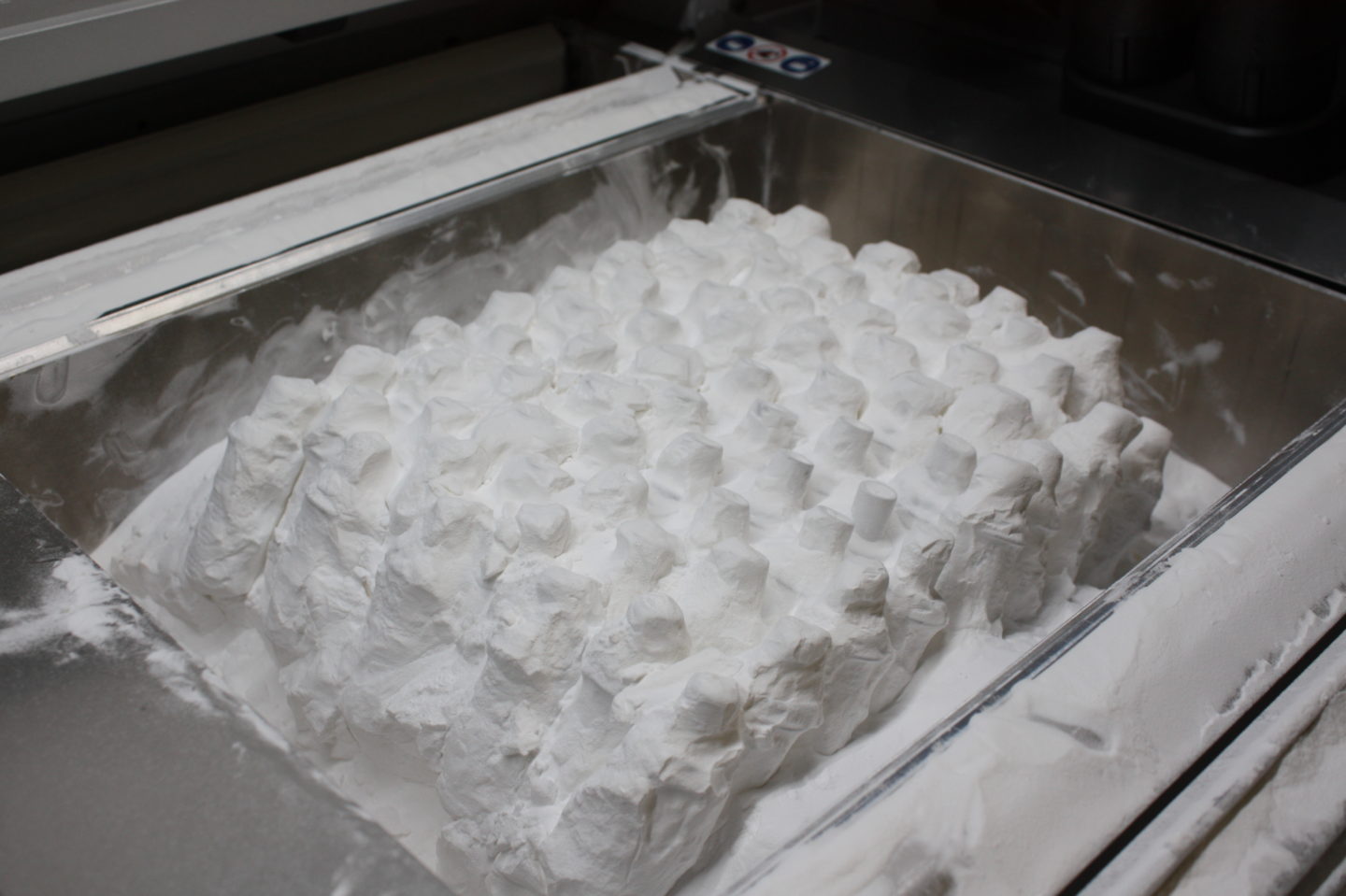

HP Multi-Jet Fusion, like SLS, is based on PA powder as print material. While in the classical SLS process plastic powders are sintered in layers by a laser beam to form a component, the connection of the powder molecules in the multi-jet fusion process, however, is carried out by a chemical flux (agent).

In combination with previous re-design of the desired components weight and thus costs can be minimized. An additional advantage of this technology is the possibility to produce thin-walled components (from 0.4mm wall thickness). Due to the fast production process, it is also possible to realize high volumes of serial components.